Sawing is more than just dividing

Against the background of demographic change, many manufacturing companies are forced to review previous production processes. A trend that has been emerging for several years is the development towards low-manned production facilities and automated production lines. With powerful circular saw systems and efficient material handling solutions, Behringer Eisele offers automated sawing lines from a single source.

Especially companies with frequently recurring orders and series production can reduce the number of skilled workers required and make their production processes more efficient with the help of automated systems and connected technologies. High-performance automatic circular saws have proven to be reliable machines for sawing bars or tubes in large batches. They are particularly suitable for series cuts and guarantee high output, low cost per cut and excellent surface quality.

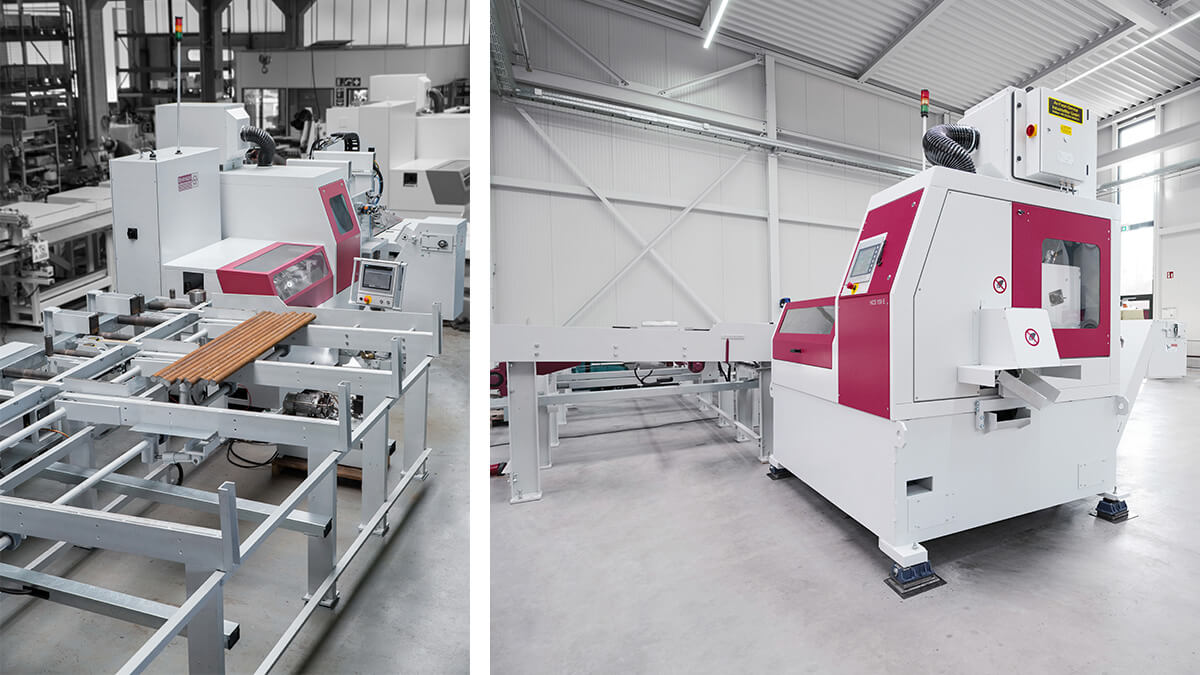

The HCS 150 E is a compact high-performance carbide ciruclar saw and prepares the entry into automated production. It cuts solid materials and tubes up to 152.4 mm (6 inches) in diameter or square material with edge dimensions of up to 130 x 130 mm. The automatic circular saw covers a wide range of industrial applications and is also an economically very cost-effective solution.

During the development of the machine concept, great importance was given to the consistent use of vibration-damping materials. The machine bed is therefore extremely robust and stable. The installed gray cast iron parts from the Behringer iron foundry also prove to be highly vibration-damping. The worm gearbox of the HCS 150 E developed by Behringer Eisele is preloaded without backlash and ensures low-vibration running of the saw blade and saw spindle. The selection of these high-quality components significantly improves the quality of the cutting surface and positively influences cutting performance and cutting costs.

Material handling as a factor of speed

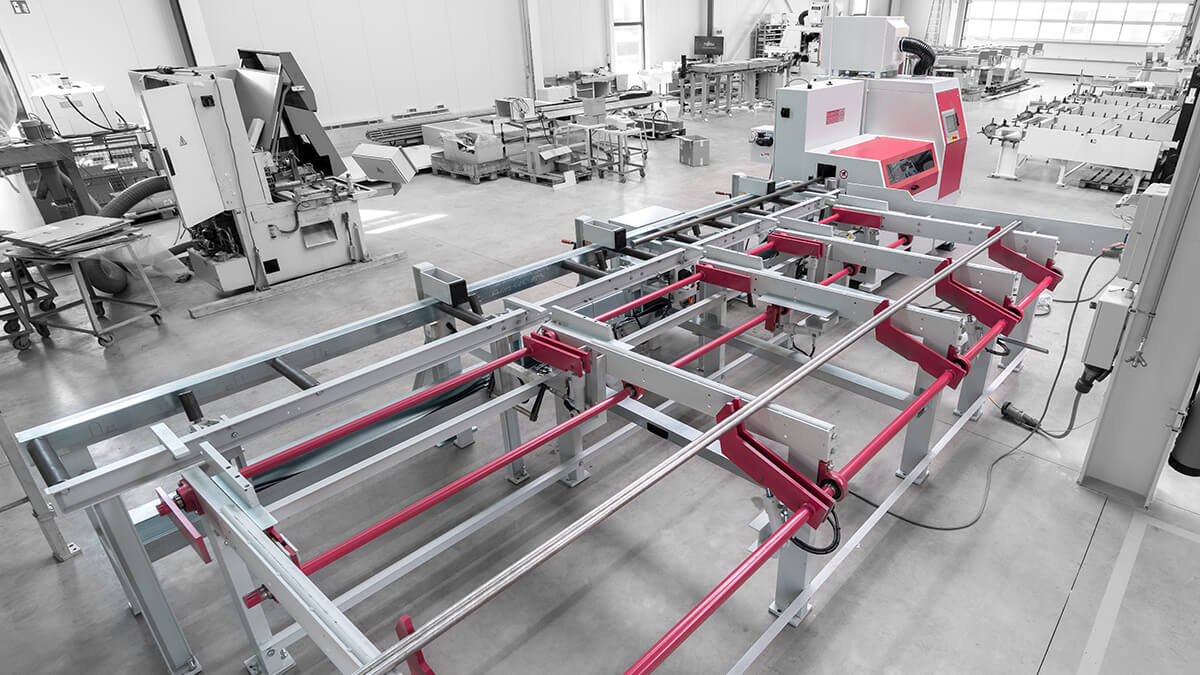

Maximum output can only be achieved if both, the sawing process and the material feed are capable of top performance. To meet these requirements, Behringer Eisele developed high-performance material handling solutions. An important approach here is reloading during machining time in order to keep unproductive idle time to a minimum. While a sawing process is still running, the following material can already be placed in the buffer area and automatically fed into the saw. The customer can choose from a wide variety of loading magazines wide variety of loading magazines for this purpose.

Bar loading magazine for round material

A bar loading magazine is the best choice for supplying the circular saw line with round material from an initial length of 2,200 mm. Round bars and pipes are usually delivered in a bundle and placed on the magazine's robust material storage. There, the bundle is opened, and the rods are distributed as a layer on the magazine.

For feeding the material to the circular cold saw, the bars are separated by a hydraulic lifting device and transferred onto the feed roller conveyor. To cover a wide range of materials from 20 mm to 150 mm diameter, the transfer device can be adjusted to the diameter to be sawn.

The roller conveyor itself is equipped with robust vertical guide rollers and stops with damping plates that are supported separately on the floor. When the bars are transferred from the buffer to the roller conveyor, the guide rollers first swivel back so that the material hits the damping stops as quietly as possible. Then the vertical guide rollers move back into position and align the bars to the machine level.

The feeding gripper, driven by servo motor and ball screw, ensures precise material positioning in the high-performance circular saw. The saw offers a controlled zero edge as standard. It ensures that the material does not touch the clamping jaws during positioning. This prevents damage and achieves a higher surface quality.

Other loading magazines

While bar loading magazines are only suitable for round material, the high-performance automatic circular saws of the HCS series can be loaded with almost all profile shapes through flat loading magazines. The bundle loading magazine with large storage capacity was developed especially for separating large bundles. When the bundle is opened, upwardly directed flanges prevent the material from jumping up in an uncontrolled manner. The separation works reliably - even with thin bars. Behringer Eisele offers the described loading magazines as standardised charging solutions. The portfolio includes even more loading options and also offers individual special solutions according to customer requirements.

Disposal devices

The standard HCS 150 E is equipped with a material chute with sorting switch for removing the cut-offs. They can be sorted separately by good parts and remnants. It is possible, for example, to dispose the cut-offs in storage boxes provided. This disposal device is suitable for cut-off lengths of up to 150 millimetres and a maximum weight of 10 kg. For more demanding applications, numerous other solutions are available, such as disposal tongs, link belt conveyors or roller conveyors with pusher units.

Behringer Eisele has responded to the structural change and designed efficient material handling systems. With the standardised loading and disposal equipment, low-manned production environments as well as automated material flows can be implemented. The HCS 150 E high-performance automatic circular saw contains all the high-quality components and technical features expected of a Behringer Eisele circular saw. Right from the start, its reliability makes a decisive contribution to the profitability of the sawing process. The investment pays for itself quickly and you enjoy the benefits of a high-performance, top-of-the-range circular saw from the very first cut.

Are you looking for efficient sawing solutions for your production?

Please contact us!

Get in touch with the project managers at Behringer Eisele by phone or email: