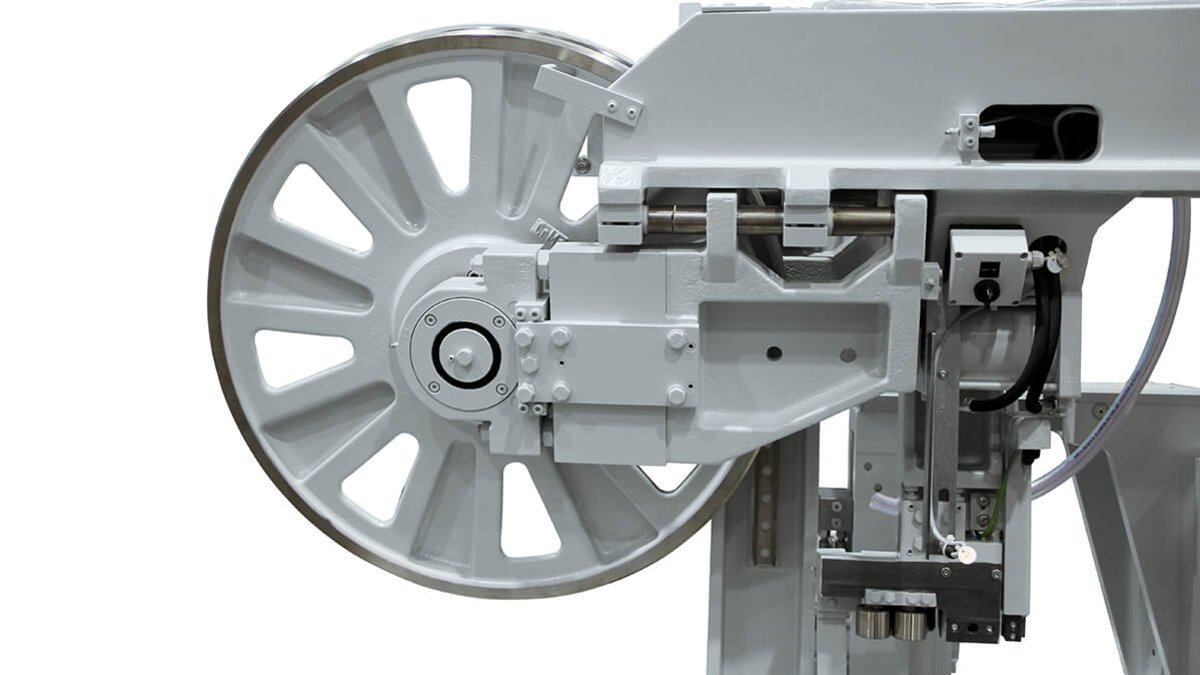

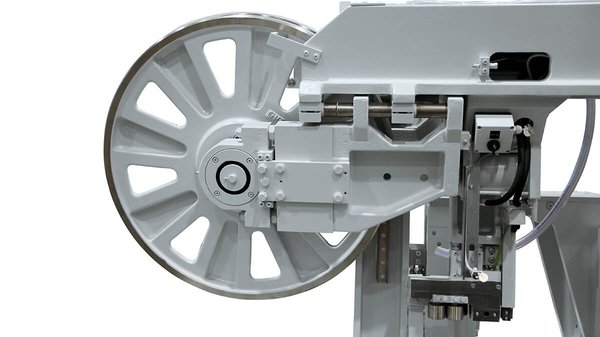

The innovative SpeedCutting technology of the HBM540A high-speed saw series allows process-reliable cutting performance that was previously unthinkable. The HBM540A shows its full potential especially when sawing tool steels to stainless steels or high-alloy materials such as Inconel or Titanium. The production bandsaw thus covers a wide range of applications in industry and the steel trade. Thanks to the combination of a powerful machine base, modern servo technology, innovative cooling system and process-reliable chip disposal, the HBM540A gets the maximum out of the tool used - regardless of whether it is a carbide or bi-metal blade.

- Prepared for automation

A powerful machine concept puts high demands on material handling. The production band saws of the HBM series are often configured as automated sawing systems. Therefore, the machines are already prepared in the basic configuration for the connection of extensive material handling equipment.

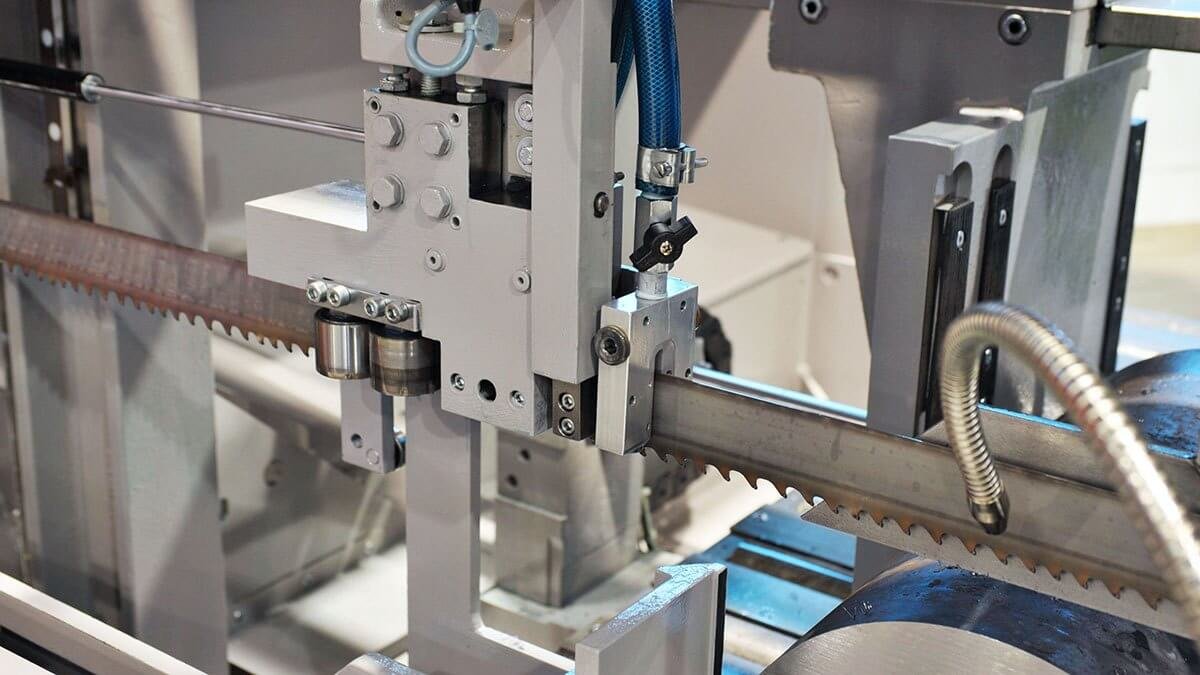

- Sensitive Behringer cutting pressure control

increases the cutting performance when sawing tubes and profiles, as it automatically adapts the saw feed of the machine to the changing material cross-sections. Due to the arrangement directly at the back of the blade, the system regulates quickly and precisely.

- Optimum chip disposal

Highest cutting performance requires high standards of chip disposal. The wide, funnel-shaped machine base allows chips to fly freely into the chip conveyor with integrated coolant tank below. The ejection height of 800 mm or optionally 1,200 mm allows the use of large chip buckets.

- Countering the shortage of skilled labour

Optimum sawing results WITHOUT prior knowledge of the operator.

- Increase your output

Significantly increased cutting performance thanks to dynamic sawing process (up to 50% depending on material).

- Wide range of materials - no problem

The extensive material database even takes tempering or electro-slag remelting (ESR) into account.

- Scalable production

The sawing know-how is in the machine control system. This allows you to easily adapt your production to changing requirements.

| Feeding length single stroke | 500 mm |

| Drive power | 7.5 kW |

| Blade speed | 13 - 130 m/min |

| Saw blade dimensions | 7,500 x 54 x 1.6 mm |

| Rest piece length in automatic operation | 40 mm |

| Total power | 12 kW |

| Saw feed | servo-feed via ball screw |

| Material feed | ball screw |

| Material clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

- production band saw

- carbide saw

- automated bandsaw

- high speed band saw machine

- automatic saw

- steel sawing

- horizontal bandsaw

- dynamic saw

- high production saw

- auto feed bandsaw

- heavy duty bandsaw

- metal cutting bandsaw

- titanium saw

- industrial band saw manufacturers

- automatic saws

- material handling

- band saw horizontal

- titanium sawing

- auto bandsaw

- programmable saw

- high speed saw

- automatic metal saw

- band sawing

- automatic band saw

- heavy duty saw

- steel saw

- autofeed bandsaw

- steel band saws

- metal bandsaw

- horizontal band saws

- automatic horizontal bandsaw

- horizontal band saw

- saw handling

- band saw machine

- automatic feed band saw

- saw machine

- machine saw

- band saw cutting