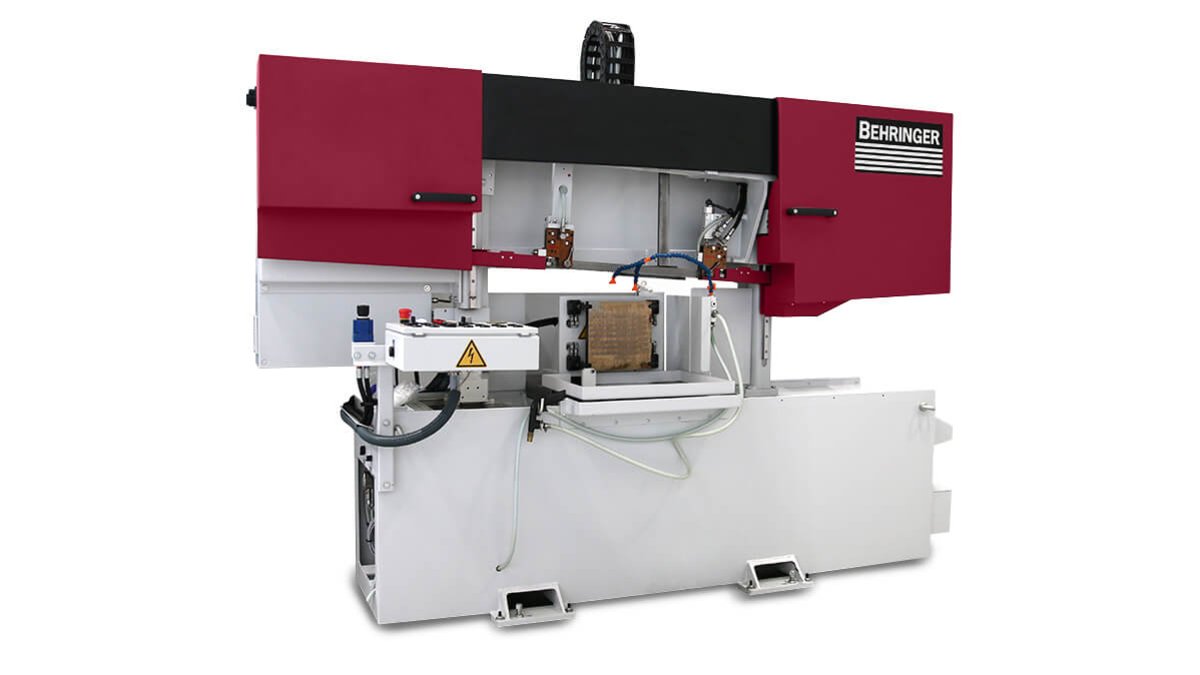

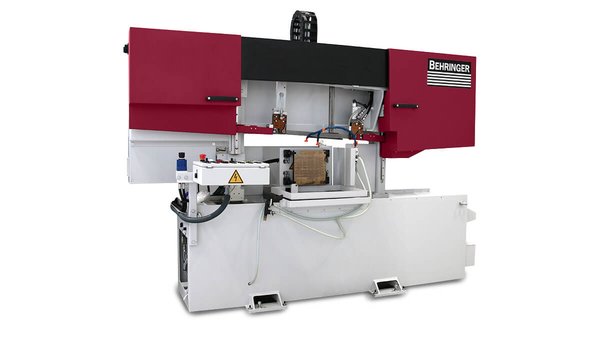

3D Saw HBE320-523 3D

The flexible sawing solution for additively manufactured components

The horizontal bandsaw HBE320-523 3D is designed for sawing 3D printing plates in different sizes up to 520 x 300 mm. The individual production of the work holding according to customer requirements offers a high degree of flexibility when sawing 3D printing plates in different sizes and shapes. The zero-point stop system with alignment to the printing plate simplifies set-up operation and reduces sources of error. The fixture of the 3D saw is movable, ensuring easy loading and handling.

In order to optimally adapt the sawing system to the specific process, Behringer offers various options such as a machine housing with extraction option, minimum quantity lubrication as well as individual clamping options according to customer requirements.

- Quick and easy loading and unloading

The shortest possible setup times are achieved because the HBE320-523 3D is equipped with a device for holding additively printed base plates. The printing plates can simply be inserted into the device by hand or by means of lifting gear. Manual alignment to the saw blade is not necessary.

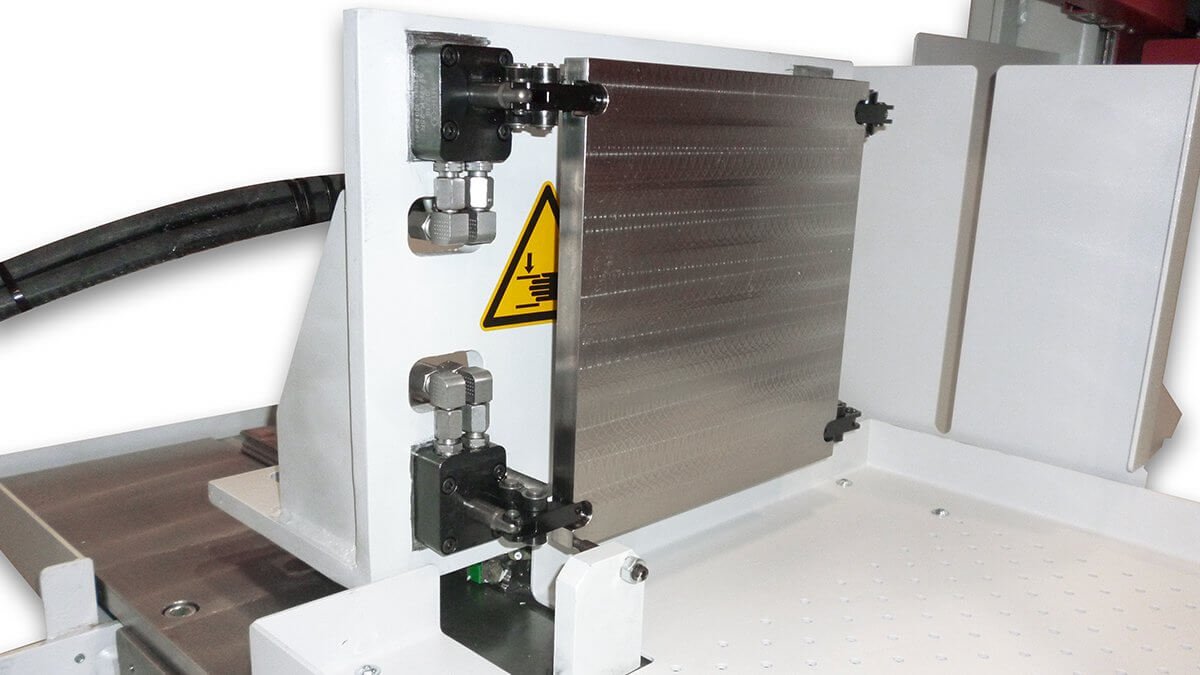

- Clamping options according to customer requirements

The workpiece holder is equipped with a customised borehole pattern as standard to attach the 3D printing plates. Individual clamping options such as hydraulic lever clamps can also be added as an option.

- Housing and exhaust system (optional)

Depending on the material of the 3D printing components and the lubricant used, dusts or vapors can be generated and released into the ambient air. To prevent this, it is advisable to use an enclosure with a connected extraction system that effectively filters both dusts and aerosols from the air.

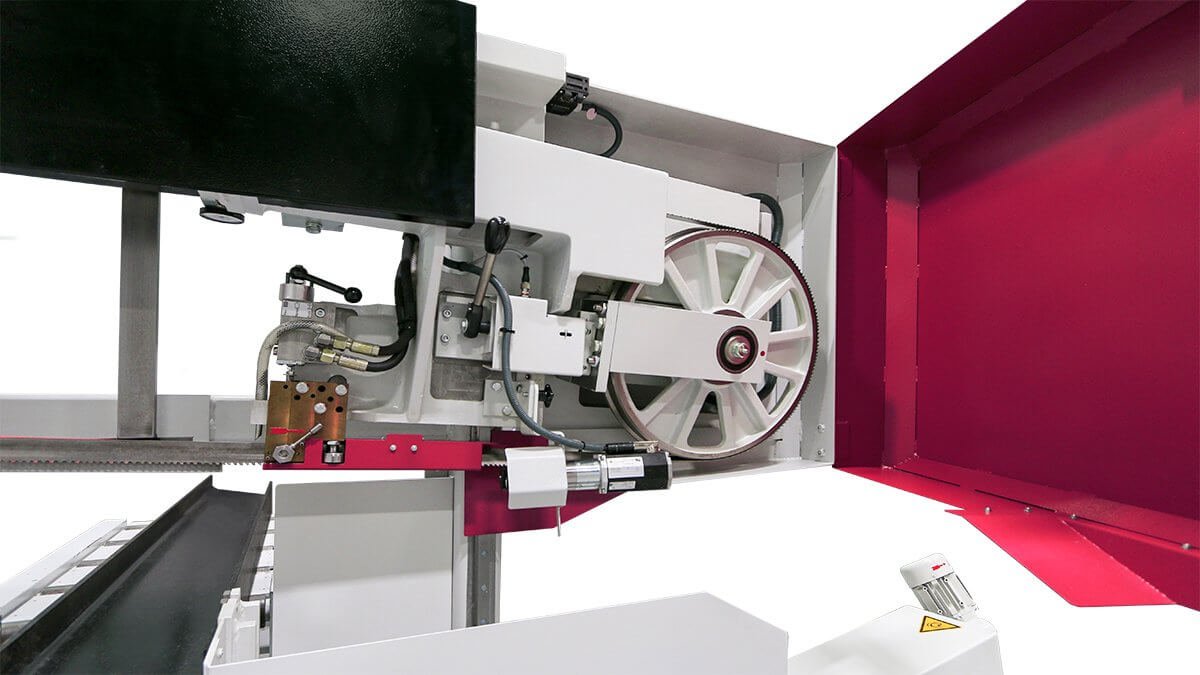

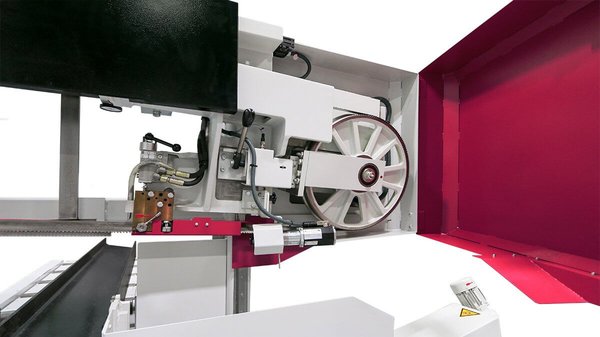

- Sensitive BEHRINGER cutting pressure control

increases the cutting performance when sawing 3D printed components, as it automatically adapts the saw feed of the machine to the changing material cross-sections. Due to the arrangement directly at the back of the blade, the system regulates quickly and precisely.

- Zero-point stop system

A clever solution for aligning the printed panels under the saw line is the standard zero-point stop system. Since the plate surface serves as a reference for positioning, no re-adjustment of the saw is required for thinning plates.

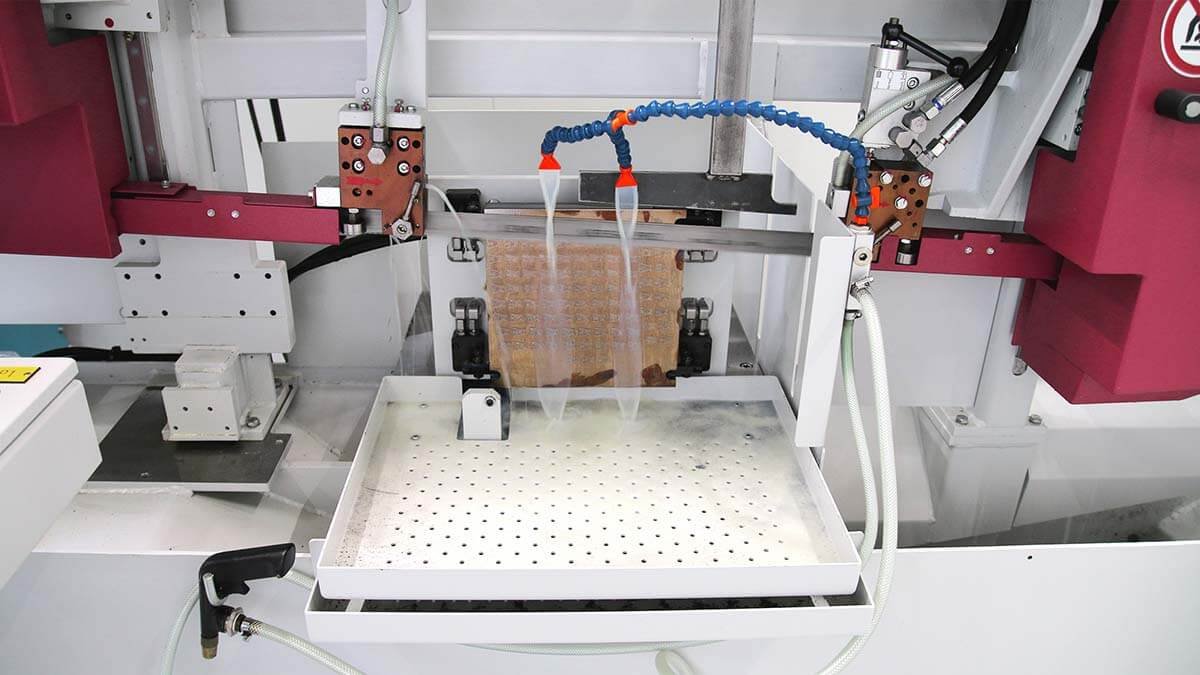

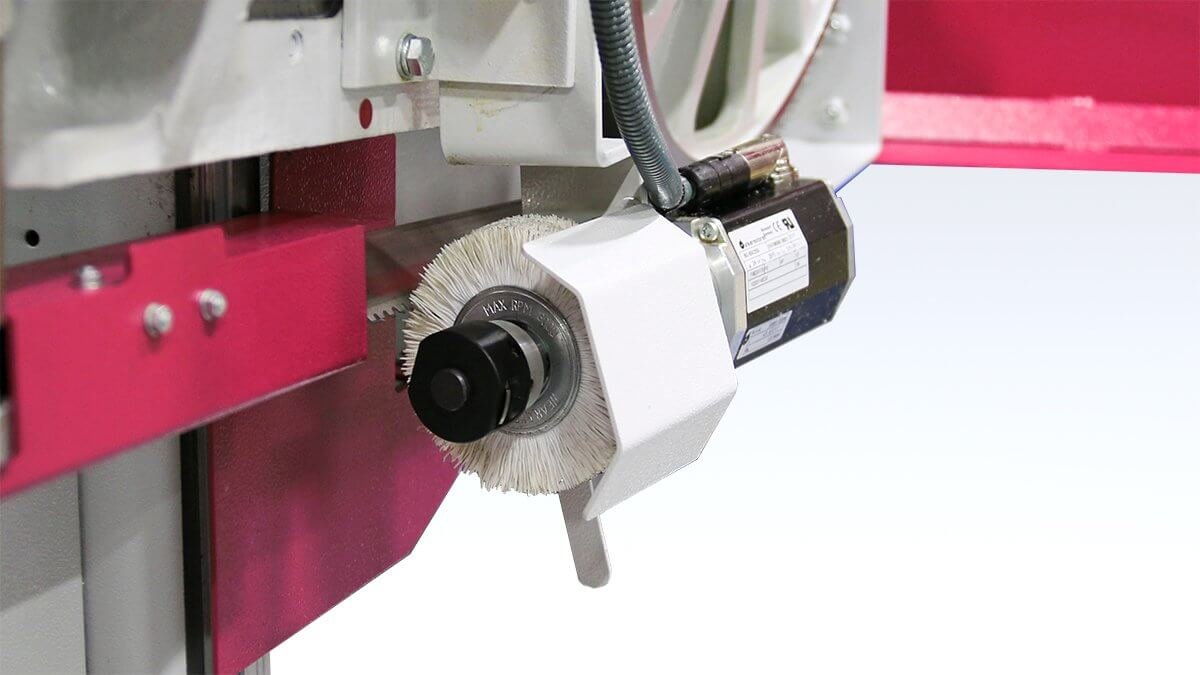

- Coolant cleaning

A standard filter unit cleans the coolant from particles and powder residues that are released during the sawing of printed components. This unit noticeably increases the service life of the coolant.

- Micro Spray System (optional)

When sawing profiles, pipes and solid material, the standard minimum quantity lubrication system delivers the best results. The saw blade is constantly moistened with cutting oil via two nozzles. This guarantees a long service life of the saw blade and a clean working environment.