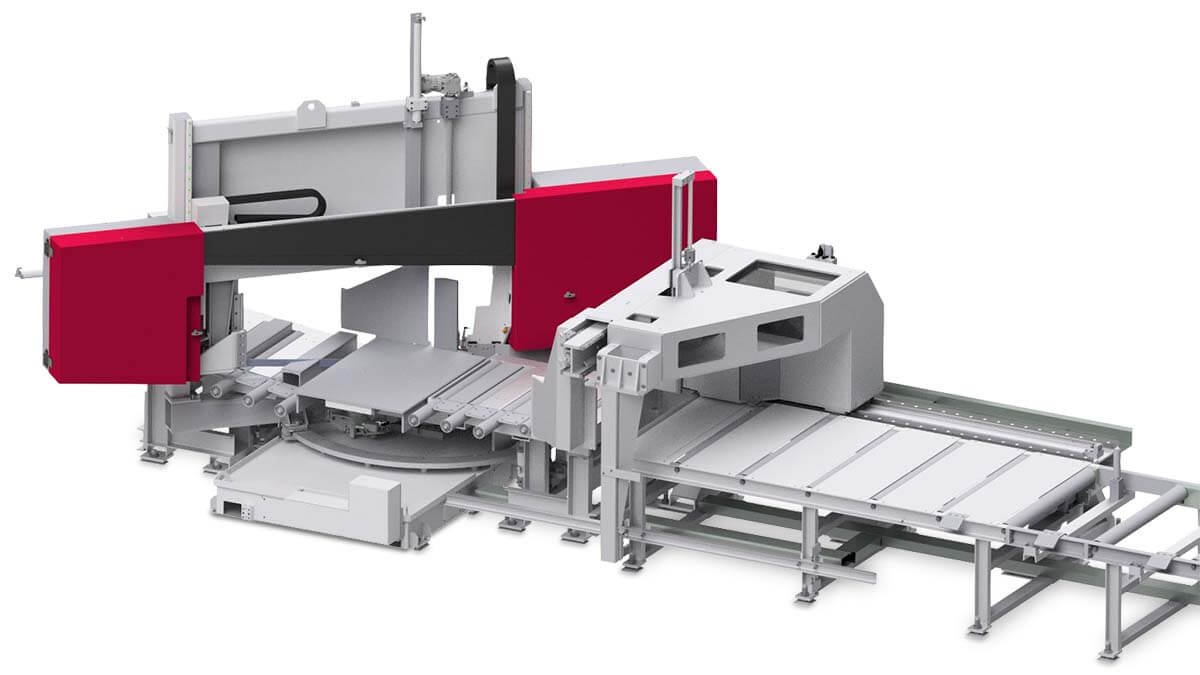

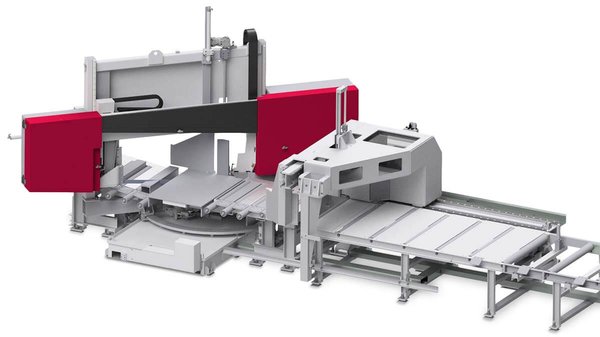

Automatic Mitre Bandsaw HBE520-926GA

for precise mitre cuts in steel construction and sectional steel trade

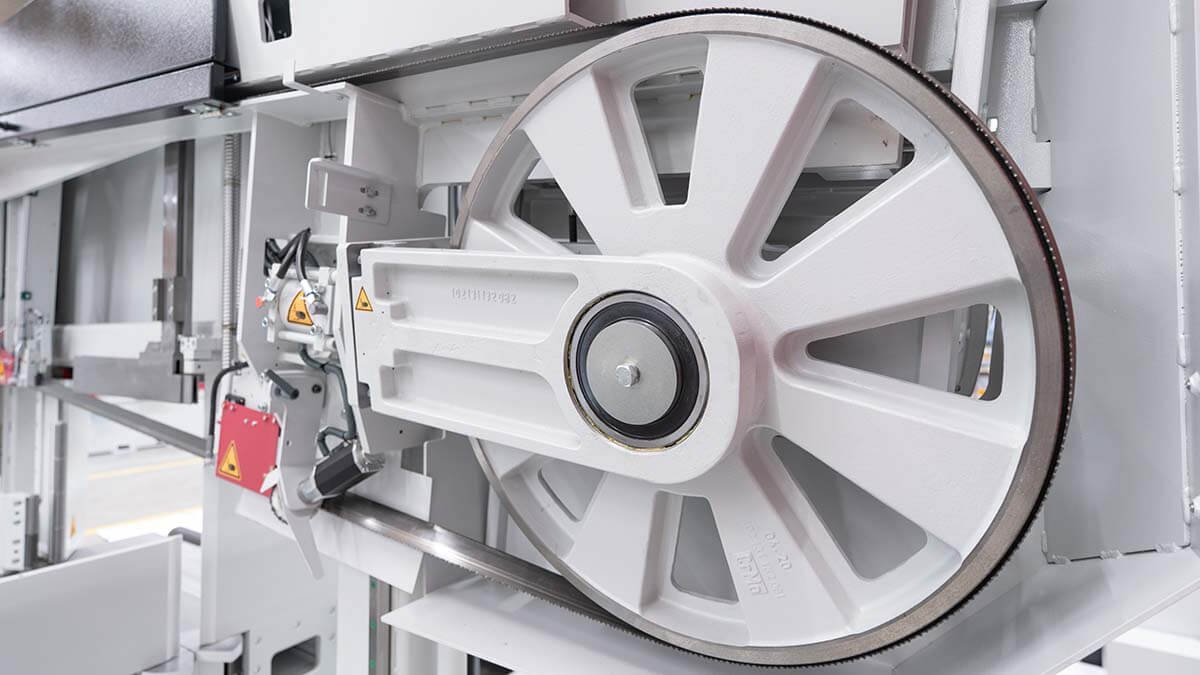

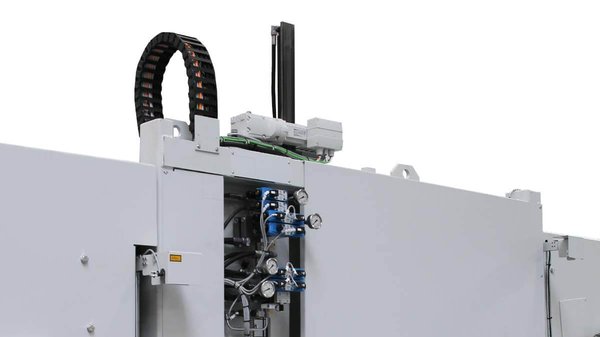

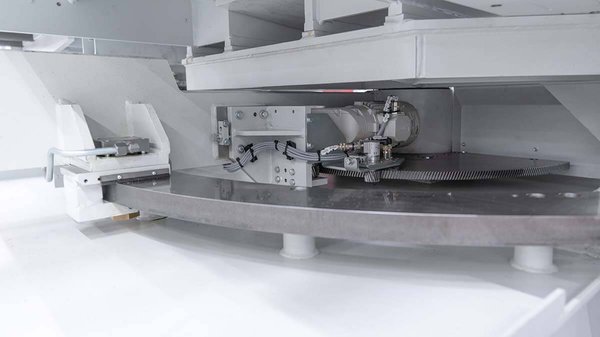

The high-performance automatic mitre band saw HBE520-926GA is designed for automatic sawing of structural steel, profiles and pipes. Features such as electronic mitre angle adjustment, saw feed with servo motor, Behringer cutting pressure control, automatic guide arm adjustment and a robust double clamping vice are provided as standard. Its stable saw frame, inclined band wheels and the use of vibration-damping cast components extend the service life of the saw bands tremendously.

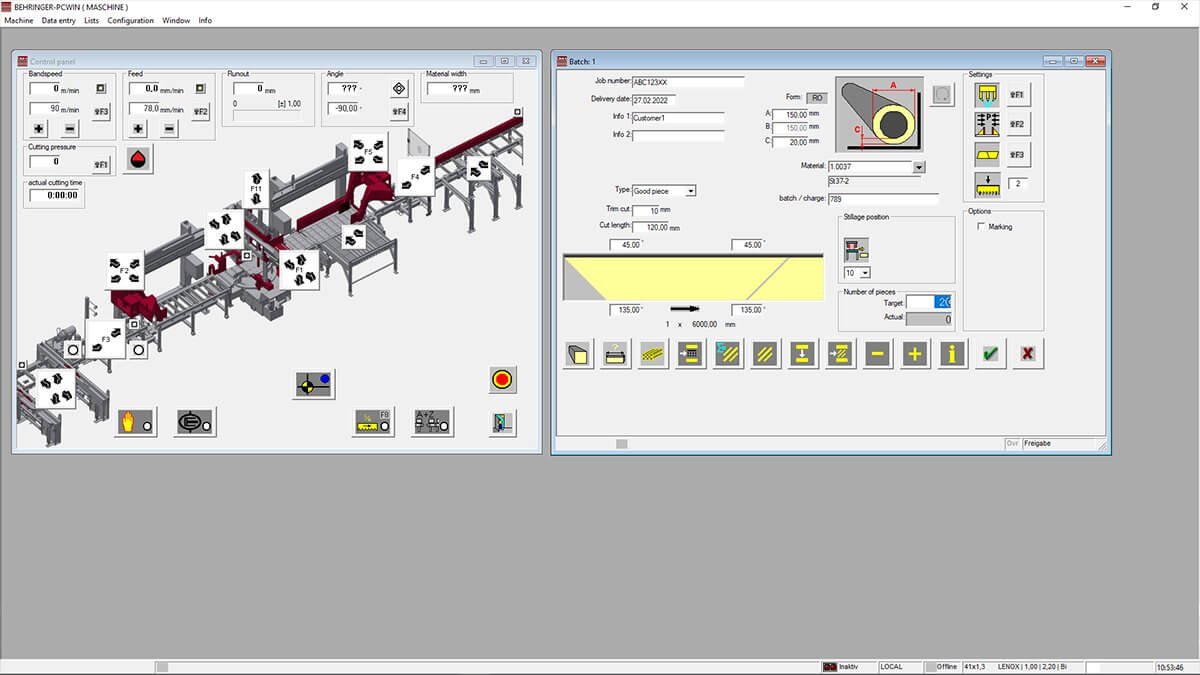

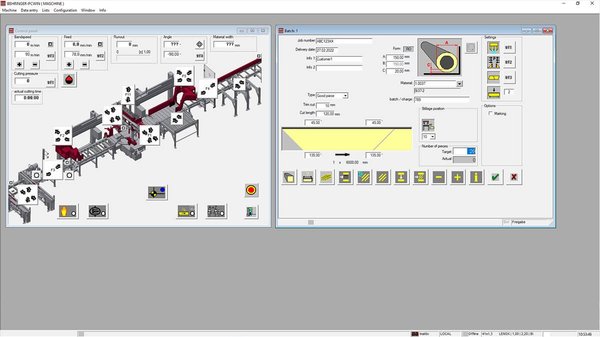

When processing large profiles, however, material handling is in addition to the cutting performance also a key factor in determining the system throughput. The HBE520-926GA computerized mitre saw is therefore consequently designed for low-operator use in automated sawing lines. Automatic material loading and discharge systems, pre- and post-buffer lines and an intelligent control system with nesting functionality cover all requirements.

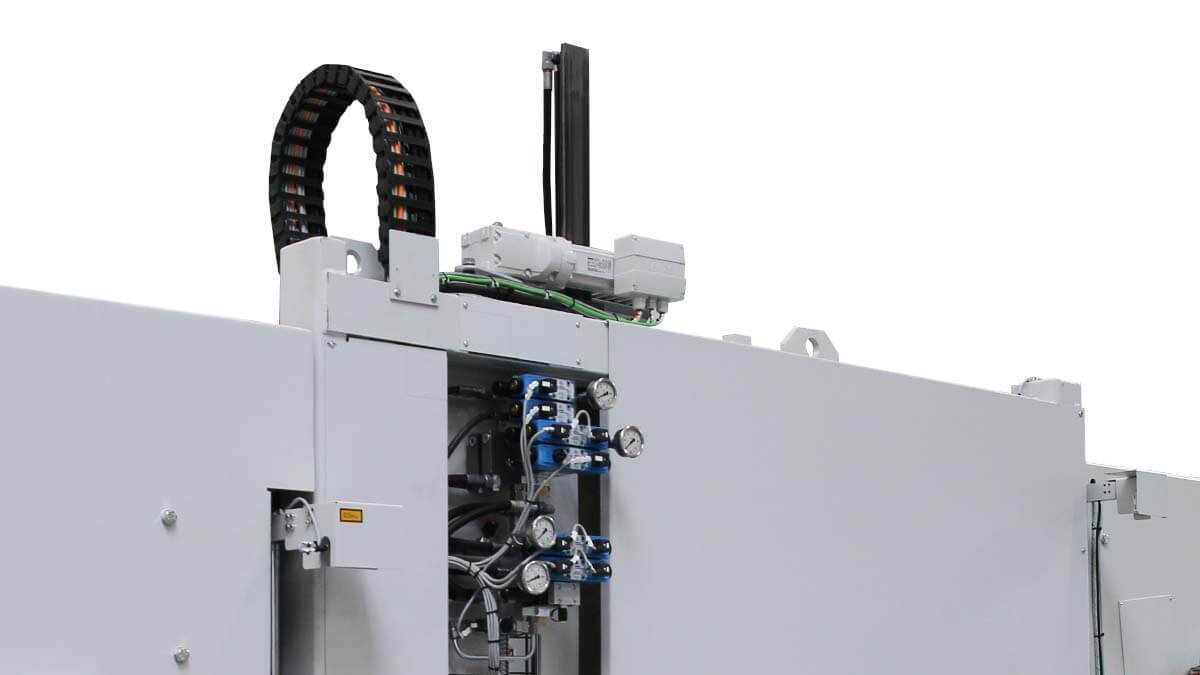

- Sensitive Behringer cutting pressure control

increases the cutting performance when sawing tubes and profiles, as it automatically adapts the saw feed of the machine to the changing material cross-sections. Due to the arrangement directly at the back of the blade, the system regulates quickly and precisely.

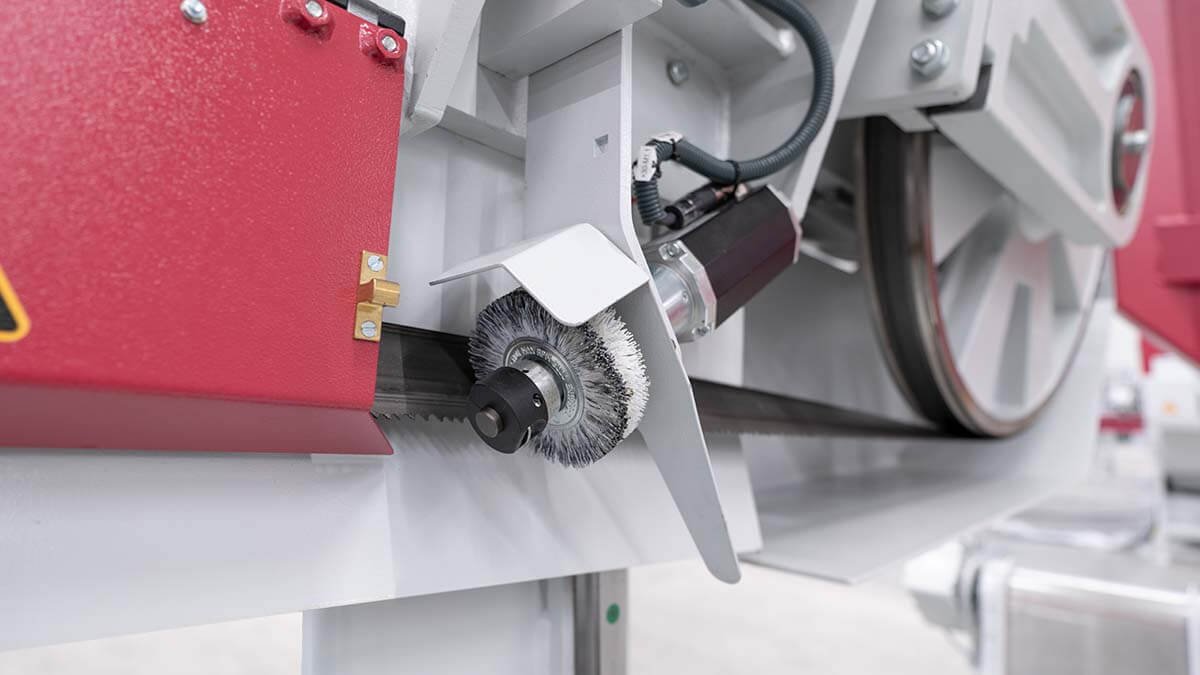

- Micro Spray System

When sawing profiles, pipes and solid material, the standard minimum quantity lubrication system delivers the best results. The saw blade is constantly moistened with cutting oil via two nozzles. This guarantees a long service life of the saw blade and a clean working environment.

| Cutting capacity 90° round | 520 mm |

| Cutting capacity 90° flat | 820 x 520 mm |

| 75° Miter left round / flat | 520 mm / 820 x 520 mm |

| 60° Miter left round / flat | 520 mm / 820 x 520 mm |

| 45° Miter left round / flat | 520 mm / 700 x 520 mm |

| 30° Miter left round / flat | 430 mm / 430 x 520 mm |

| 75° Miter right round / flat | 520 mm / 820 x 520 mm |

| 60° Miter right round / flat | 520 mm / 820 x 520 mm |

| 45° Miter right round / flat | 520 mm / 700 x 520 mm |

| Smallest dimension to be sawn round | 20 mm |

| Smallest dimension to be sawn flat | 20 x 20 mm |

| Feeding length single stroke | 3,000 mm |

| Drive power | 5.5 kW |

| Blade speed | 17 - 120 m/min |

| Saw blade dimensions | 8,500 x 54 x 1.6 mm |

| Rest piece length in automatic operation | 150 mm |

| Minimum cut length | 55 mm |

| Total power | 11 kW |

| Saw feed | servo-feed via ball screw |

| Material feed | servo motor via gear rack |

| Material clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

- automatic mitre saw

- automatic mitre band saws

- automatic mitre bandsaw

- automatic beam saws

- tube cutting saw

- pipe cutting saw

- mitre saw measuring system

- mitre saw machine

- mitre band saw

- mitre cutting machine

- profile machining

- band sawing

- horizontal bandsaw

- horizontal band saw

- horizontal mitre bandsaw

- metal band saw

- metal cutting bandsaw

- automatic band saws

- automatic feed bandsaw

- automated bandsaw

- structural steel band saw