Customer-specific sawing systems: Loading magazines

The demand for short cycle times, improved surface quality and automation places stringent demands on material handling.

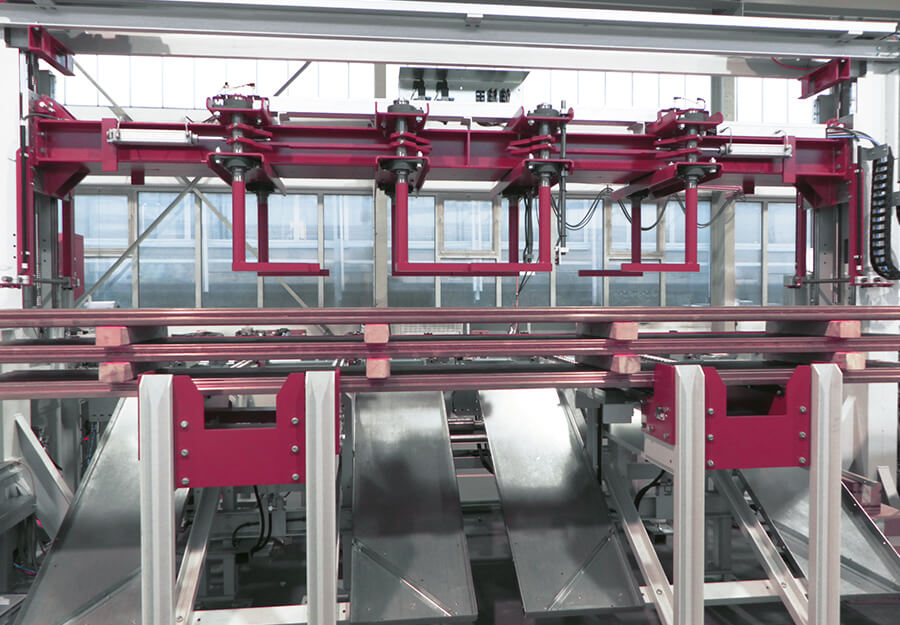

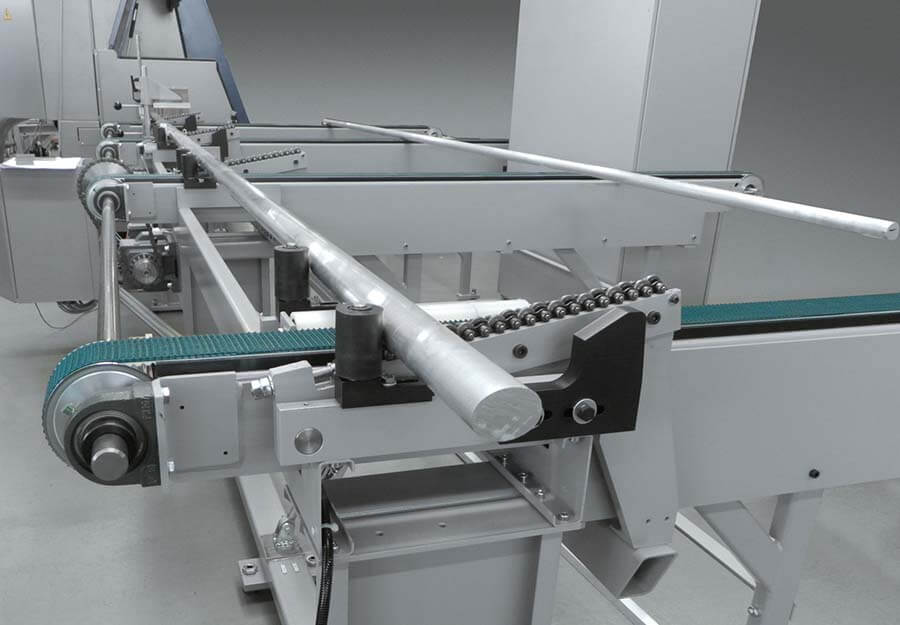

Make sure you make the very most of the VA-L’s performance potential: Using a material feed system configured ideally to the sawing process, you can maximize your sawing output. Our approach to maximized potential: Parallel reloading and productive time. To minimize set-up times, the next material load is positioned and automatically fed during the previous sawing process. Just like the circular sawing machines themselves, the design of our loading magazines consistently seeks to minimize material damage. Bars being fed into the saw are handled by a gripper which takes optimum care of the surface. For loading, different loading magazines can be used.