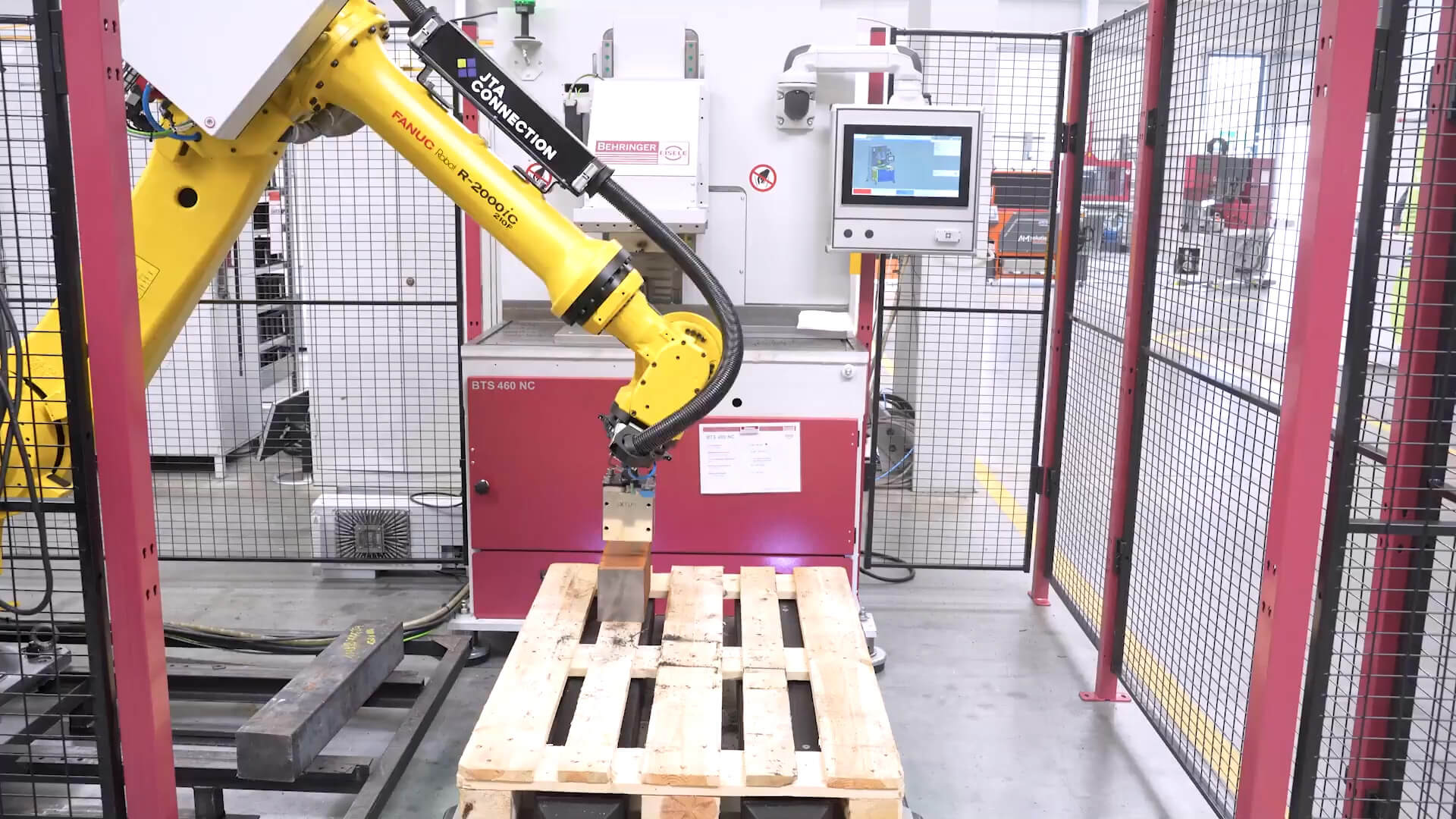

Carbide Circular Saw BTS 460 NC

High speed sawing of bent tubes with carbide blades

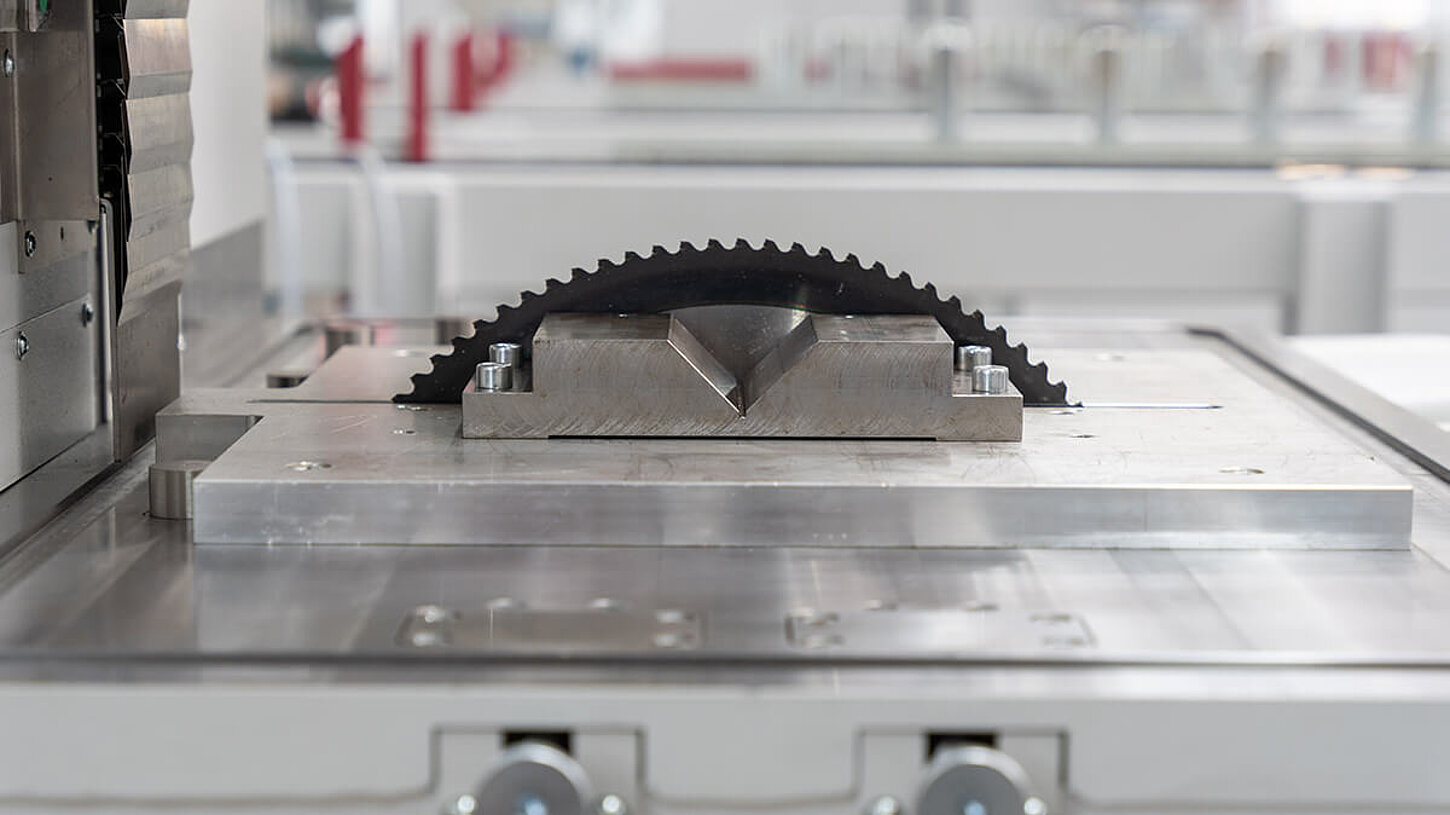

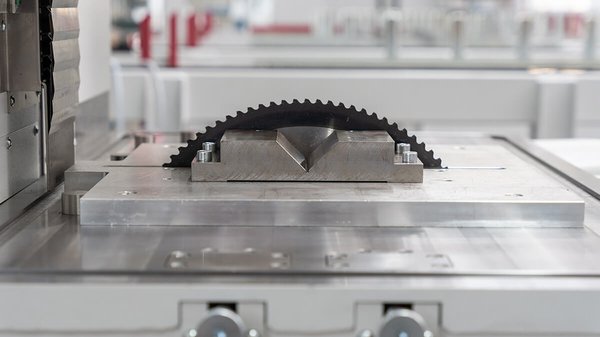

The BTS 460 NC is a carbide circular saw specially designed for sawing curved tubes such as mufflers, hydroforming or exhaust pipes. Standardised mounts and their flat material table enable individual workpiece fixtures to be accepted. The saw entry and exit point can be freely adjusted accordingly. The standard two-hand operation allows comfortable and safe working without disturbing mechanical guards.

The heart of the BTS 460 NC is the high-performance sawing unit from the HCS series and powerful servo axes for saw feed and material clamping. This overall concept offers a powerful and low-vibration sawing process, which ensures a good cutting surface, long saw blade life and a long service life of the saw.